Description

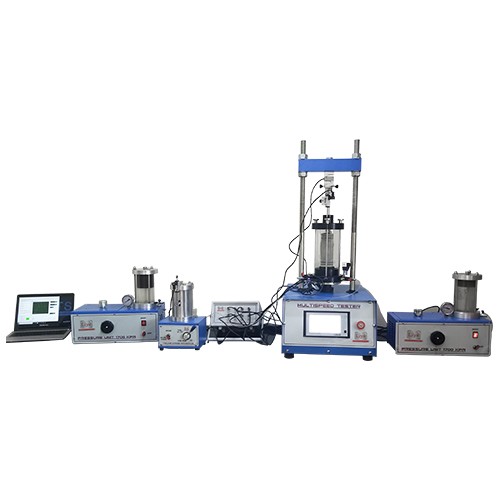

LIYA TEST SOIL TRIAXIAL TEST SYSTEM FOR UU-CU-CD

Determining the mechanical properties of soils is a very important step to design foundations, embankments and other soil structures. Building constructions, excavations, tunnelling and similar applications have several effects on the subsoil structures and these effects are successfully simulated with Triaxial Tests where the stress-strain relation of undisturbed soil specimen are investigated by subjecting the soil sample to different stress levels and drainage conditions.

The Liya Test Triaxial Test System provides automated triaxial compression tests on cylindrical undisturbed and remolded soil samples. Unconsolidated undrained (UU), consolidated drained (CD) and consolidated undrained (CU) compression tests can be automatically run, controlled and reported using this apparatus.

Unconsolidated Undrained (UU) Test

For the UU test, the specimens (assumed to be saturated prior to test) are subjected to a confining fluid pressure in a triaxial chamber. Once the specimen is inside the triaxial cell, the cell pressure is increased to a predetermined value by rotating the knob of the constant pressure unit, and the specimen is brought to failure by increasing the vertical stress by applying a constant rate of axial strain. Since saturation and consolidation do not exist in this method, original structure and water content of sample is untouched. Pore and back pressures are not measured during this test and therefore the results can only be interpreted in terms of total stress over a confinement pressure (stress).

These tests are generally carried out on three specimens of the same sample subjected to different confining stresses.

Since all specimens are supposedly saturated the shear strength are similar for all tests.

The results of the test are plotted as curves of principal stres difference against strain. For conditions of maximum principal stress difference (taken as failure) Mohr circles are plotted in terms of total stress. The average undrained shear strength is recorded, and the failure (Mohr) envelope is drawn tangential to the Mohr circles in order to find the “undrained cohesion intercept” and undrained “angle of shearing resistance”.

Consolidated Undrained (CU) Test & Consolidated Drained (CD) Test

Peak effective strength parameters (c’ and φ’) can be determined either from the results of consolidated undrained (CU) triaxial compression tests with pore pressure measurement or from consolidated drained (CD) triaxial compression tests. The consolidated undrained/ drained triaxial compression tests are normally performed in several stages, involving the successive saturation, consolidation and shearing of each of three specimens.

Saturation is carried out in order to ensure that the pore fluid in the specimen does not contain free air. Saturation is normally carried out by leaving the specimens to an elevated back pressure so that the air in the pores is dissolved in water. Back pressure (which is simply an imposed pore pressure) is applied through a volume change gauge to the top of the specimen, while a cell pressure of slightly higher value is also applied. Both cell pressure and back pressure are normally increased in increments, allowing time for equalization at each stage.

The consolidation stage of an effective stress triaxial test is carried out for two reasons. First, three specimens are tested and consolidated at three different effective pressures, in order to give specimens of different strengths which will produce widely spaced effective stress Mohr circles. Secondly, the results of consolidation are used to determine the minimum time to failure in the shear stage.

The effective consolidation pressures (i.e. cell pressure minus back pressure) will normally be increased by a factor of two between each specimen, with the middle pressure approximating to the vertical effective stress in the ground. When the consolidation cell pressure and back pressure are applied to the specimen, readings of volume change are made using a volume change device in the back pressure line. Pore pressure is measured at the specimen base, with drainage to the back pressure line taking place through a porous stone covering the top of the specimen.

The coefficient of consolidation of the clay can be determined by plotting volume change as a function of the square root of time. Theoretical considerations indicate that the first 50% of volume loss during consolidation should show as a straight line on this plot. This straight line is extended down to cut the horizontal line representing 100% consolidation, and the time intercept at this point (termed “t ” by Bishop and Henkel) 100 can be used to obtain the coefficient of consolidation.

Consolidated Undrained (CU) Test:

Once consolidation is complete, the specimen is to be isolated from the back pressure and the rate of vertical movement of the compression machine platen set according to result of consolidation. During the shear stage the vertical stress is increased by the loading ram and measurements are made at regular intervals of deformation, ram load and pore pressure. These are converted to graphs of principal stress difference (σ1- σ3) and pore pressure as a function of strain, and failure is normally taken as the point of maximum principal stress difference. The effective stress Mohr circles are plotted for the failure conditions of the three specimens which has been subjected to different consolidation level, and the gradient and intercept of a straight line drawn tangential to these circles defines the effective strength parameters c’ and φ’.

Consolidated Drained (CD) Test:

The consolidated drained triaxial compression test, with volume change measurement during shear is carried out in a similar sequence to the consolidated undrained test, but during shear the back pressure remains connected to the specimen which is loaded sufficiently slowly to avoid the development of excess pore pressures.

The shear stage of a drained triaxial test can be expected to take between 7 and 15 times longer than that of an undrained test with pore pressure measurement.

Once shearing is complete, the results are presented as graphs of principal stress difference and volume change as a function of strain, and the failure Mohr circles are plotted to give the drained failure envelope defined by the parameters cd’ and φd’ .

Triaxial CD-CU-UU equipment is computer controlled, test values can be transferred to computer and data processing can be made with Triaxial software on Windows operating system. All data can be used on Excel programs.

The load data and axial displacement data are transferred and recorded through 7″ TFT Touch Screen Control Unit to the software.

Three pressure data (cell pressure, back pressure and pore pressure) from triaxial cell and volume change data transferred and recorded through the interface unit with 4 channel for data acquisition to the software.

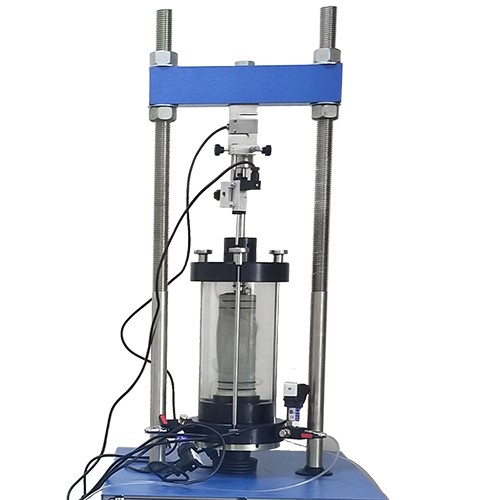

Multispeed Testing Machine is used to make Uniaxial and Triaxial Tests.

The device is composed of a robust and compact two column frame with adjustable upper cross beam driven by an electromechanical ram with a maximum capacity of 50 kN.

This versatile digital loading frame features a microprocessor controlled drive system with an advanced servo motor enabling the operator to easily set any test speed via the membrane keyboard. The keyboard comprises adjustment buttons such as “start”, “stop”, “down”, “up”. The testing speed can be set between 0,001 mm/min to 51mm/min. The test automatically stops when load and displacement is reached to 99% value of the set measuring range.

The Servo Controlled Multispeed Universal Electromechanical Testing Machine is supplied complete with 50 kN Load Cell, 25 mm Displacement Sensor and Digital Readout and Control Unit.

The other Test Accessories should be ordered separately according to the test.

Technical Specifications:

| Product Code | LT-E0450/TX |

| Product Name | Multispeed Testing Machine |

| Test Speed (mm/min) | 0,001 – 51 |

| Capacity (kN) | 50 |

| Dimensions (cm) | 47x61x115 |

| Weight (kg) | 105 |

| Power Supply | 220 V, 50-60 Hz, 1 ph |

The Triaxial Test System provides Automated Triaxial Compression Tests on cylindrical undisturbed and remolded soil samples. Unconsolidated Undrained (UU), Consolidated Undrained (CU), Consolidated Drained (CD) Compression Tests can be automatically run, controlled and reported using this apparatus.

5 kN Load Cell should be ordered separately for Triaxial Tests.

Unconsolidated Undrained (UU) Test

For the UU test, the specimens (assumed to be saturated prior to test) are subjected to a confining fluid pressure in a Triaxial chamber. Once the specimen is inside the Triaxial cell, the Cell Pressure is increased to a predetermined value by rotating the knob and the specimen is brought to failure by increasing the vertical stress by applying a constant rate of axial strain. Saturation and consolidation are not permitted to keep the original structure and water content of sample untouched. Pore pressures are not measured during this test and therefore the results can only be interpreted in terms of total stress.

These tests are generally carried out on three specimens of the same sample subjected to different confining stresses.

Since all specimens are supposedly saturated the shear strength are similar for all tests. The results of the test are plotted as curves of principal stress difference against strain. For conditions of maximum principal stress difference (taken as failure) Mohr circles are plotted in terms of total stress. The average undrained shear strength should be noted, and the failure envelope drawn tangential to the Mohr circles in order to find the “undrained cohesion intercept” and undrained “angle of shearing resistance”.

The System is Supplied with Multispeed Testing Machine, Load cell, 5 kN capacity, Triaxial Cell for ∅ 38 and ∅ 50 mm samples , Analog Manometer, Oil and Water Constant Pressure System, Software to Perform UU Triaxial Tests and De-Airing Water Tank and Hose.

Triaxial Cells

The cell has been designed and treated to minimize corrosion. Particular attention has been paid to the quality of finish between the piston and the head. Final assembly includes the fitting of an O-ring seal and the use of a special lubricant to reduce friction to a minimum and eliminate water leakage. The piston load capacity is designed to accept high axial loads which may be present during the final stages of a test.

Each cell has 3 take-off positions drilled in the base for top drainage/back pressure, pore water pressure and bottom drainage. Each cell will accept a range of base adaptors(38/50 or 70/100 mm) and various accessories for testing a wide range of specimens.

The cell capacity is 1700 kPa which is enough for simulating most in-situ conditions.

Technical Specifications:

| Product Code | Product Name |

| LT-E0450 | Multispeed Testing Machine |

| LT-G8030 | Load cell, 5 kN capacity |

| LT-S0320 | Triaxial Cell for ∅ 38 and ∅ 50 mm samples |

| LT-S0325 | Triaxial Cell for ∅ 70 and ∅ 100 mm samples |

| LT-G9005 | Analog Manometer |

| LT-G9010 | Digital Manometer (Optional) |

| LT-S0500/2 | Oil and Water Constant Pressure System |

| LT-S0500/3 | Software to Perform UU Triaxial Tests |

| LT-S0500/4 | De-Airing Water Tank, 7 lt |

| LT-S0500/5 | Plastic Hose, Ø 8 mm x 6 m |

Technical Specifications for Triaxial Cells

| Product Code | Product Name | Dimensions (cm) | Weight (kg) |

| LT-S0320 | Triaxial Cell for ∅ 38 and ∅ 50 mm samples | 16x16x40 | 4.5 kg |

| LT-S0325 | Triaxial Cell for ∅ 70 and ∅ 100 mm samples | 21x21x55 | 12 kg |

Triaxial Cell Accessories

Product Code | ||||

Sample Diameter (mm) | 38 | 50 | 70 | 100 |

Base Adaptor | LT-S0330 | LT-S0350 | LT-S0370 | LT-S0390 |

Porous Top Cap | LT-S0331 | LT-S0351 | LT-S0371 | LT-S0391 |

Nylon Tubing for Drainage | LT-S0332 | LT-S0352 | LT-S0372 | LT-S0392 |

Pair of Porous Discs | LT-S0333 | LT-S0353 | LT-S0373 | LT-S0393 |

Rubber Membrane | LT-S0334 | LT-S0354 | LT-S0374 | LT-S0394 |

Membrane Placing Tool (Strecher) | LT-S0335 | LT-S0355 | LT-S0375 | LT-S0395 |

0 Ring (Pack of 10) | LT-S0336 | LT-S0356 | LT-S0376 | LT-S0396 |

0 Ring Placing Tool | LT-S0337 | LT-S0357 | LT-S0377 | LT-S0397 |

Lateral Filter Paper (Pack of 50) | LT-S0338 | LT-S0358 | LT-S0378 | LT-S0398 |

Filter Paper Discs (Pack of 100) | LT-S0339 | LT-S0359 | LT-S0379 | LT-S0399 |

Plastic Discs (Pack of 2) | LT-S0340 | LT-S0360 | LT-S0380 | LT-S0400 |

Sample Preparation Accessories

Product Code | ||||

Sample Diameter (mm) | 38 | 50 | 70 | 100 |

Split Sand Former | LT-S0300 | LT-S0305 | LT-S0310 | LT-S0315 |

Split Mould | LT-S0301 | LT-S0306 | LT-S0311 | LT-S0316 |

Cutter | LT-S0302 | LT-S0307 | LT-S0312 | LT-S0317 |

Aluminum Dolly | LT-S0303 | LT-S0308 | LT-S0313 | LT-S0318 |

Oil and Water Constant Pressure System

The Oil and Water Constant Pressure Unit is extremely versatile and can be used in conjunction with a wide range of test equipment. The unit provides continuous variable pressure up to 1700 kPa. Pressure is increased or decreased simply by turning a control wheel.

The Unit is used for providing cell/back pressure in Triaxial tests. The apparatus is supplied without a gauge for those customers who have suitable pressure monitoring equipment.

As optional equipment for monitoring the pressure of the unit;

- Digital Manometer or

- Analog Manometer

can be used and preferred optional equipment should be ordered separately.

The machine features a clear hydraulic/water interface reservoir and up to 1 liter capacity of water is available under pressure.

Technical Specifications:

| Product Code | Product Name | Dimensions (cm) | Weight (kg) | Power Supply |

| LT-G9005 | Analog Manometer | — | — | — |

| LT-G9010 | Digital Manometer | — | — | — |

| LT-S0500/2 | Oil and Water Constant Pressure Unit, 1700 kPa | 30x25x25 | 7.5 kg | 220-240V, 50-60Hz, 1ph |

Uniaxial Test Systems

STANDARDS: ASTM D2166, AASHTO T208

Compression Platens, used to perform uniaxial and unconfined compression tests.

Supplied complete with ball seating assembly.

Technical Specifications:

| Product Code | Product Name |

| LT-S0500/10 | Compression Platens with ball seating assembly |