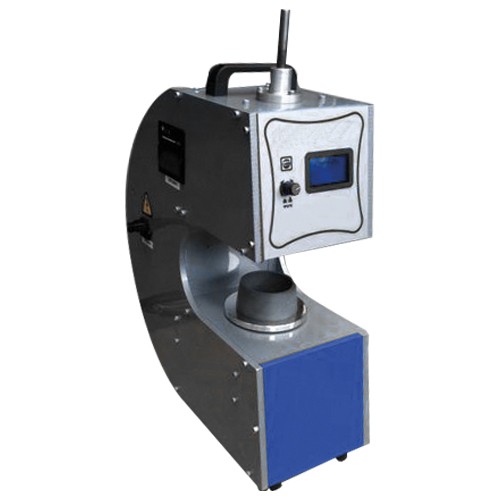

Description

The setting time determination of cement/mortar/gypsum is one of the most important parameter for the quality inspection and verification. The machine is based on the innovative CVI-TECH philosophy. On the machine, a needle (or a probe) drops freely into a cement sample at regular intervals and in fixed positions. Penetration depth is measured by a sensor with 0,1 mm resolution. Along with hardening process development the penetration depth decreases, when it matches some thresholds pre-defined by Standards initial and final setting times are measured and recorded.

Main Features

- Functional and ergonomic design based on the innovative CVi-TECH philosophy.

- Advanced electronics technologies providing superior performances and total flexibility combined With simplicity in use

- Easy-to-use double interface: local mode, with large size 4,3″ touch screen color display and remote mode with PC

- Supplied complete with PC software for data processing VICASOFT-BASIC

- With PC software VICASOFT-PREMIUM (optional) up to 32 indipendent units can be connected to a single PC via LAN port and hub. All units are remotely controlled. Adopting the multi-test network concept laboratory productivity is maximized

- Integrated graphic printer is available as optional accessory showing both results in numerical format and setting time plot

- Easy setting and storage of user-defined test profiles allowing quick test start

- Large accessibility to the test space

- Practical in-water testing accessory (optional)

- Automatic determination of initial and final setting time

Technical Specification

- Conforming to EN 196-3, 13279-2, 480-2, ASTM C191, C187

- Large size 4,3″ touch screen color display

- LAN port for direct connection to PC of a single unit or connection to a LAN hub for creating a network with up to 32 independent units all controlled by a single PC. 1 LAN cable is included

- USB port for data storage on pen-drive (included)

- Test procedures can be customized and stored to match user-defined requirements

- Can incorporate an integrated graphic printer showing test result and setting time plot

- Large test space with easy accessibility

- Automatic calculation of initial and final setting time at programmable penetration depth limits

- Wide range of accessories including EN and ASTM/AASHTO parts, in-water testing kit, needle cleaning device, integrated printer, probes for testing consistency and gypsum

- Minimum penetrations rate: 10 seconds

- Penetration measurement by encoder

Firmware Specifications

Easy programming of customized test profiles, recallable for future tests, including:

- Adjustable test start delay

- Penetration points positions

- Manual or automatic penetration rate

- Free or driven dropping mode

- Holding intervals inside the sample

- Automatic end- test detection

- Automatic measurement of initial and final setting time

- Test data: test number, operator, client, date, hour, cement type, water percentage, delay

- Easy calibration menu

- Clock calendar

- Multi-language

Accessories

- Accessory for Needle Continuous Cleaning and In-Water Testing

- LAN hub for PC connection of up to 7 VICAMATIC- 2 units or up to 6 units in case of multi-hub network. LAN cable from hub to PC is included. Each VICAMATIC-2 unit is supplied complete with LAN cable.

- Upgrading of a VICAMATIC-2 unit for incorporating a graphic printer into the head. Test settings and results are plotted both as numerical and graphical format including penetration depth/time diagram. The upgrading shall be factory installed.

- Needle for Final Setting Test EN

- Cylindrical Probe for Consistency Test

- Additional Weight 700 g,

- Water thermostatic unit for VICAMATIC-2. Up to 2 units may be connected. 230 V, 50-60 Hz, 1 ph.

- Conical penetration probe 8 mm dia x 50 mm complete with 100g calibrated weight for gypsum testing to EN 13279

- Cylindrical probe and addition weight for consistency test to ASTM C807.

- 2 mm dia. needle to ASTM C807

- Brass cylindrical mould to ASTM C807

- VICASOFT-PREMIUM Software for PC connection of up to 32 VICAMATIC-2 units including remote control of each unit, data acquisition – processing – filing, printout of test reports.

- Communication via LAN port (each VICAMATIC-2 unit is supplied complete with LAN cable). The connection of one VICAMATIC-2 unit is direct via the PC LAN-port, for more VICAMATIC-2 units (up to 32) one or more LAN hubs are required with total number of ports equal (or bigger) to the number of VICAMATIC-2 units included in the network. LAN hubs are not included.

Spare Parts

1,13 mm dia. needle for initial setting time test to EN

1 mm dia. needle for setting time test to ASTM/AASHTO

- Plastic mould to EN

- Plastic mould to ASTM/AASHTO

- Glass base plate

- Spare base plate for in-water testing kit

- Centering ring for EN vicat mould

- Cenitering ring for ASTM vicat mould