Description

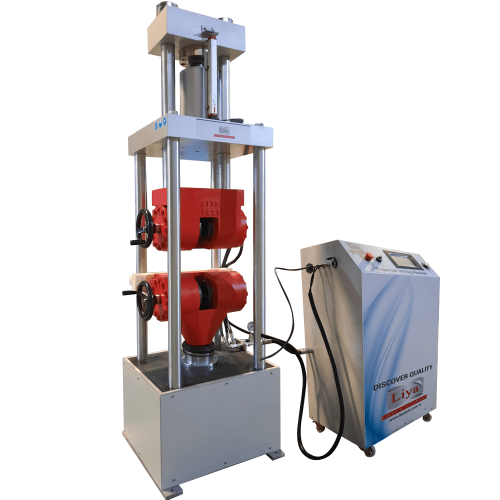

Computer Control Electromechanical Universal Testing Machine is designed according to ASTM, ISO, DIN, EN etc. standards. It is computer controlled precision testing machine, suitable for extensive metallic & nonmetallic materials for tension, compression, bending, shearing and cycle test etc. It features as high precision, high stability as well as high reliability. Equipped with PC system & printer, graph, test result display, data processing and printing can be done easily. Complete with modulus for metal, spring, textile, rubber, plastic and other material testing. It is widely used in many fields of R&D, QC and QA and education institutes.

Table Type

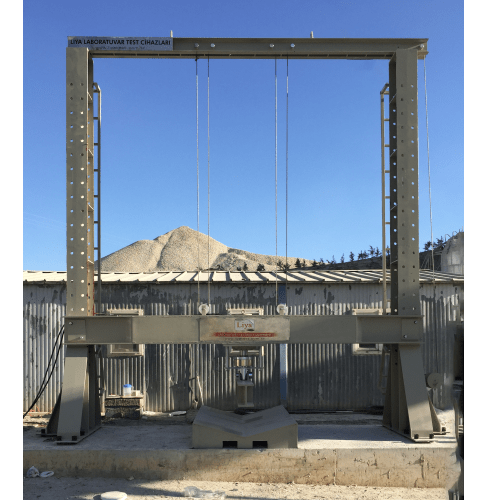

The design purpose of this load frame with double columns is to ensure safety, reduce operator fatigue and provide the highest level of flexibility. Concretely, it features as following:

• High accuracy: the preloaded precision ball-screw eliminates the backlash & ensures position measurement accuracy. A builtin scale on the frame indicated the crosshead position for verification of normal strain testing

• Safety features: equipped with the upper and lower limit switches, testing machine can stop automatically when applied test force exceeds the specified value during operations.

• Large space in the working area: the distance between columns provides wide space for the operator.

• Over-stroke limiter: the range of the crosshead movement mechanically limited.

• Comfortable working area: the wide legroom under the load unit provides a comfortable working area for attaching and removing jigs.

ECONOMICAL ELECTROMECHANICAL UNIVERSAL TESTING MACHINE

This testing machine is designed for tensile mechanical property test on metallic or nonmetallic materials as per ASTM, ISO, DIN, GB standards. A variety of fixtures can be offered to do compression, bending and shearing test as well. It is suited for the applications in quality inspection, research, metallurgy, rubber & plastics, and knitting materials, and widely used in many fields such as industry factories, mineral enterprise and high schools.

Special Applications for Electromechanical Testing Machines:

Liya Test device has extensive experience in providing the electromechanical testing machine with different configurations to meet various applications. With different kinds of grips (manual, hydraulic & pneumatic type), it can clamp different specimens. With furnace or climatic chamber, it can do test under a certain temperature condition. With different extensometers, it can do various testing according to international standard or customers’ requests.

Grips

Liya Test has great experience in producing customized solutions for particularly difficult applications. Please keep in minds that we have extensive customs design capabilities, so please contact us to discuss your requirement.

Software

Liya Test software refers to the characteristics of the famous brands of testing machine in the world and proposals of various testing requirements from end users, and combines all the major advantages of earlier versions of software with lots of new features. Optimized software structure makes the testing operation easy, convenient and powerful.

The control mode, test data and curves can be displayed in real time in the main interface and can be switched at any time. Data sampling rate can be set per the testing requirement.

The deep-seated parameters of software are contained in Debug Toolbox.

With the flexible language edited function, it supports Multi-language such as English, Chinese, Portuguese, French, Spanish, Italian, Turkish and Polish etc. You can translate the software language into native language by yourself.

Software supports all kinds of popular testing standards i.e. ISO, ASTM, BS EN, DIN, JIS, GB etc.

Users can modify and add own testing standards and method as your requirement.

MaxProgram Editor possess of multi-kinds full digital control modes, i.e Displacement control, Stress (Load)

Control, Strain (Deformation) control, Low cycle control. Users can edit the most complex and logical procedure by MaxProgram

Editor. The combination of above functions can meet all kinds of routine test purpose.

Multiple curves function, real time display including Load-Extension, Load-Displacement, Stress-Strain, Load-Time, ExtensionTime,

and Width-Extension Characteristic points such as Elastic Modulus, Yield points, Rp, Rm etc. can be marked on the curves, for a direct and highlighted observation.

Test result automatically can be obtained and also it can be manually got from the test curves.

Through the Tensile Program Editor, user can setup test steps according to standards’ requirement.

Liya Test software contains all kinds of Report Templet. Customer can design various testing reports according to the requirement.

The test result and the curve can be printed in Excel or printed in the auto-creating report templet.

Except the clip-on Extensometer, Liya Test software supports Long Travel Extensometer, Full Automatic

Extensometer, Video Extensometer, Laser Extensometer and up to eight Extensometers.

Environment of Testing Machine

- Operating temperature: +10 to +38ºC

- Storage temperature: -40 to +66°C

- Humidity range: +10% to +90%, non-condensing

- Atmosphere: Designed for use under normal laboratory conditions. Protective measures may be required if excessive dust, corrosive fumes, electromagnetic field or hazardous conditions are encountered.Controllers:

There are three kinds of controllers to meet different applications:

1.PCI CARD

It is self-developed & most advanced card for testing machine to realize the functions of real time data collection, communication, measuring and control etc. according to related ASTM, ISO standards. It can be inserted PCI slot of computer and connected with testing machine by data cable, then above functions can be done easily.

Effective sampling rate can be up to 50Hz, in addition, the different versions for sampling rate of 200Hz, 500Hz and 10 kHz are available as options to meet special test requirements. Besides applying for static tests, such card with related configuration is also able to be utilized for low cycle dynamic fatigue test up to 6Hz.

2.FULL DIGITAL CONTROLLER

It is super smart test instrument developed for both simple & complex tensile and compression testing of metallic & nonmetallic materials.

The controller,as a result of applying of the advanced technology, refined design and elaborate units, is of quite precision of test, accurate identification’s capability and convenience of operation. Effective sampling rate can be up to 50Hz, also, special controllerwith 10 kHz sampling rate is available as options according to special requirements. Digital, LED and touch screen can be selectable for both economical type and high configuration testing machines. Three or more channels for load, displacement, extension and others can be configured with this controller to meet the different test requirements.

3.EDC CONTROLLER

EDC controller is imported from Germany and widely used for testing machine with high configuration or Requirements. It features as stable control, high accurate measuring and high sampling rate (1~5 kHz) etc. Also, it can self-identify & self-calibration functions. Up to now, it is most reliable device to be used extensively for static and dynamic testing machines.