Description

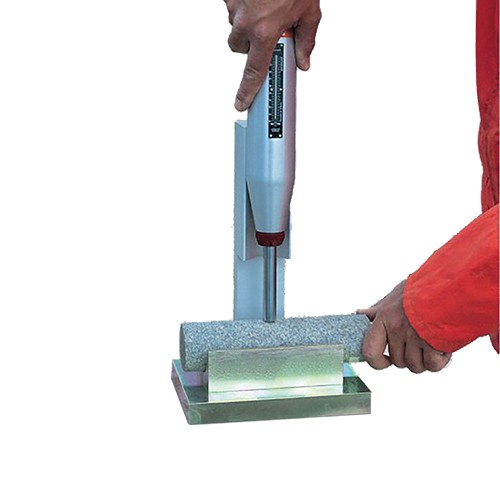

The test covers the determination of consolidated drained Shear/ Consolidation strength of a soil/rock material by direct Shear/ Consolidation. Automatic Direct Shear/Consolidation Test Machine is motorized. Normal stress is applied to the specimen by automatic consolidation unit with servo motor control. Consolidation unit can can receive up to 100 kN of load .The machine is supplied with a Shear/Consolidation box bowl that accepts 150 mm cylinder, 300 mm square, Shear/Consolidation boxes. Shear/Consolidation box is designed to contain water to inundate the specimen during the test.Drive unit utilizes a high-resolution servomotor and a gear box assembly to ensure continuously variable transmission of speed in a range from 0.001 mm-min. to 3 mm-min for both forward and reverse directions. 100 kN load cell is used for load measurement. 10 x 0.001 mm and 25 x 0.001 mm sensitivity linear potentiometric transducers are used for vertical and horizontal displacement measurements respectively. Displacement limits are controlled by limit switch.

Control Unit for Direct/Residual Shear/Consolidation Test

The Control Unit for Direct Shear/Consolidation Test is designed to control the machine to perform direct Shear/ Consolidation test acc. to EN,ASTM/AASHTO and BS standards to process.

The Unit can perform direct Shear/Consolidation tests as a stand-alone without the use of a PC or with the software and a PC. Control of machine, acquisition of load and displacement data in real time are provided by the unit

The unit has easy to use menu options. It displays all menu option listings simultaneously, allowing the operator to access the required option quickly to activate that option or enter a numeric value to set the test parameters and see all the data while the test running.

The graphic display allows real time Load vs. Displacement or Stress vs. Displacement graph. The advanced functions for data base management provide an easy navigation of all saved data.

Main Features

- Can make the test with displacement control.

- Real time display of test graph.

- 4 analog channels for load cell and displacement sensor.

- Calibration function for channels.

- Programmable digital gain adjustment for load-cell and potentiometric sensors, voltage and current transmitters.

- Closed-loop PID for steady pace rate.

Testing

- The machine run with the speed determined by user to the direction of Shear/Consolidation and stop when the load decreases.

- The machine run with the speed determined by user to the direction of Shear/Consolidation and stop when it reaches to the target horizontal displacement value which is also determined by the user at the beginning of the test.

- By using the control unit, consolidation before Shear/Consolidation tests are possible.

- The screen displays load, Shear/Consolidation stress, horizontal and vertical displacements, and τ-Δx graph continuously.

Software for Direct/Residual Shear/Consolidation Test

Direct Shear/Consolidation Software is developed in accordance with ASTM D3080, BS 1377:7 and AASHTO T 236 standards to be used with Machine. Direct Shear/Consolidation software consist of two sections. First section is used for the consolidation of the sample prior to Shear/Consolidation.

The second section of the software is capable of performing three different types of tests. The first type moves the machine with the speed determined by user until a Shear/Consolidation failure occurs.

The software supports 5 different normal load values in order to calculate cohesion (C) and internal friction angle (Ø) values.

Prior to the test normal load value must be entered to the software.

The normal stress is calculated according to normal load and sample size automatically.

The software supports both square and round type samples.

Stress values can be optionally and automatically calculated as “standard area” and the “corrected area” approach. When the test is completed peak and residual stress values are recorded.

The normal load versus peak stress pair is used for the calculation of cohesion and internal friction angle value. At least 3 loading with different normal loads are required for this property.

One can set test speed, axis values etc. through the setup of the software. The results can be submitted as a report or can be exported to Microsoft Excel for advanced reanalyse procedures.

The Automatic Direct Shear/Consolidation /Consolidation Test Machine is supplied complete with;

- 2x Load Cell 100 kN

- Linear Potentiometric Displacement Transducer (10×0.001 mm)

- Linear Potentiometric Displacement Transducer (25×0.001 mm)

- Software